Supra MP

- Globally Available

- Excellent Economic Supply

- Stocking and Quick Match Programs Available

- U.S. WARRANTY Coverage and Support

- Custom Formulations available

- Long Term International Commercial and Industrial experience

System Overview

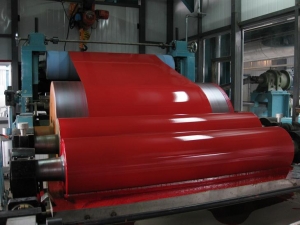

Supra MP coil coating system manufactured and distributed globally by Continental Coatings Inc. and Yung Chi Paint and Varnish Manufacturing Company Ltd., is a Modified Polyester (MP) coil coating system engineered for interior and exterior applications that require long lasting performance and excellent economics. The MP system can be applied single coat or as a two coat system depending on end use requirements and application specifics. The MP system is formulated with a proprietary polyester resin polymer, which is economical, U.V. and weather resistant, and has primer like adhesion performance. Supra MP may be applied singlecoat or over the Universal PU-11 High Molecular Weight Urethane Primer or PU-30 High-build Urethane primer systems for extreme environment and long service life product applications.

Application Parameters

Supra MP system is designed for trouble free high line speed coil coating line application and has been run worldwide under a very wide range of application parameters and substrate conditions. Standard topcoat DFT is .60-.70 mils, however, custom low film and low temperature cure systems are available. RMP was formulated to provide very good stain, scratch, mar and scuff resistance, and is flexible enough for most tough fabrication applications.

Commercial Uses

Supra MP system can be formulated in standard, medium, textured, and low gloss / low sheen finishes and supplied in a very wide range of colors and effects. This economic coating does carry a limited exterior warranty when required and can be applied to a variety of adequately cleaned and treated metal substrates including: Hot Dipped Galvanized, ZnAl, Galfan®, ZAM®, Aluminum, and Stainless Steels. Supra MP is formulated with an excellent balance of flexibility and hardness but can be custom modified for specific applications that require unique or special physical property performance. Supra MP system is ideal for many general interior and exterior applications like rain gutter and downspout, car ports, shade and shelter, Liner Panel, commercial doors, and various white goods including sign blank and lightingRegular Modified Polyester Coil Coating System

| APPLICATION | ||

| SPECIFICATIONS | TEST | RESULT |

| Application Method | Reverse Roll Coat | |

| Primer | PU11 HMW PU, PU30 High Build PU | |

| Substrate | Aluminum, HDG, Galvalume®, ZAM® | |

| Pretreatment | Standard clean and treat | Chrome, Zinc Phosphate, or approved non-chrome |

| ASTM D 4138 | Dry Film Thickness | Top coat: 0.7 to 0.8 mils Primer: 0.0 to 0.3 mils Total system: 0.6 to 1.1 mils |

| ASTM D 4212 | Viscosity (No. 4 Zahn cup) | 25 to 35 seconds |

| ASTM D 1475 | Weight Per Gallon | 9.0 to 12.0 Pounds Per Gallon |

| ASTM D 2697 | Solids Per Volume | 50 to 55% |

| ASTM D 2369 | Solids Per Weight | 60 to 75% |

| Reducing Thinner | Reducing Solvent | Aromatic |

| ASTM D 3960 | VOC (Theoretical) | 3.0 to 4.0 Pounds Per Gallon |

| Clean-up Solvent | Aromatic/Ketone | |

| Coating Mileage | 1069 to 1357 Sq. Ft. / Gallon | |

| Peak Metal Temperature | 435 F to 450 F | |

| TECHNICAL DATA | ||

| SPECIFICATIONS | TEST | RESULT |

| ASTM D 523 | Specular Gloss at 60 | 6 to 85 |

| ASTM D 3363 | Pencil Hardness | H TO 3H |

| ASTM D 4145 | T-Bend | 1T to 4T with no loss of adhesion |

| ASTM D 5402 | Solvent Resistance (MEK Rubs) | 100 + |

| ASTM D 3359 | Cross Hatch Adhesion | No loss of adhesion |

| ASTM D 2794 | Reverse Impact | Galvalume or HDG: 3x metal thickness inch-pounds, no loss of adhesion Aluminum: 1.5x metal thickness inch-pounds, no loss of adhesion |

| ASTM B 117 | Salt Spray Resistance 1,000 hrs. Salt Spray Resistance 2,000 hrs. | Galvalume or HDG: Creep from scribe < 1/8 inch (3mm), none or few #8 blisters Aluminum: Creep from scribe < Creep from scribe < 1/8 inch (3mm), few #8 blisters |

| ASTM D 2244 ASTM D 4214 | South Florida Exposure | Color: No more than 5 (E) Hunterunits at 90 vertical angle and 7 (E) unitsnon vertical Chalk: Rating no less than 8 at 90 angle and 6 at non vertical angle Film Integrity: 20 years, no blisters, peeling or cracking |

| ASTM D 870 | Water Immersion 100 F 168 hrs. | No field blisters with minimal color change |

| ASTM D 1308 | Chemical Resistance (15 mins.) | No significant color change (color dependent) |

| ASTM E 84 | Flame Spread Classification | Class I or A |

| ASTM D 968 | Abrasion Resistance | Total Sand = 35 +/- 5 liters (Dft dependent) |

|

|

|

|

|

|

|

|